General

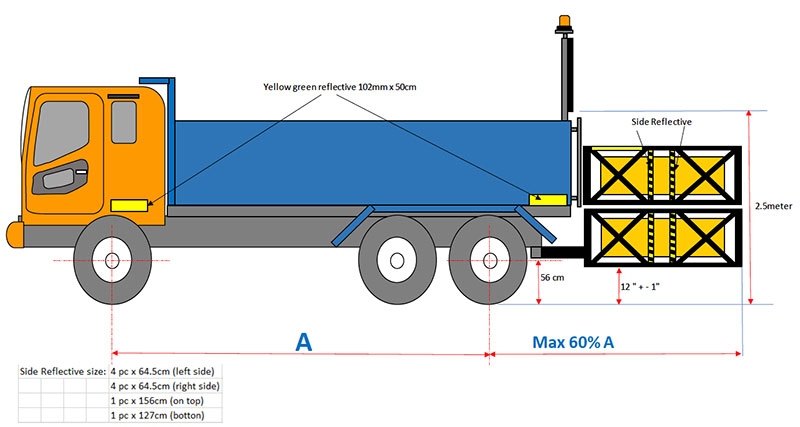

The primary objective of these guidelines is to provide a standard guidance for the application for TMA to be used on public roads.Refer to Figure A for the Use of TMA for Roads Works.

Definitions

“TMA” used refers to truck_mounted attenuator.

“User” used hercinafter is defined as the contractor/agencies who are using the TMA (regardless of self-ownership or rental) on public roads of posted speed of 70km/h or more.

“Operators” used hereinafter is defined as the person who has been trained and certified by TMA manufacturer authorised trainer/centre to correctly perform the TMA He may also double up as the shadow vehicle driver.

“Shadow Vehicle” is defined as the LTA-approved truck where the TMA is mounted on.

“NCHRP” refers to National Co-operative for Highway Research Program commissioned by American Association of State Highway and Transportation Officials and US Federal Highway Administration.

“MASH” refers to Manual for Assessing Safety Hardware. The rewrite of NCHRP 350 and was review by the ASSHTO Technical Committee on Roadside Safety (TCRS).

Compliance

Truck mounted attenuator unit mounted on the shadow vehicle shall meet both the mandatory and optional requirements as stated in the MCHRP 350 Report TL-3 or the AASHTO Manual for Assessing Safety Hardware TL-3 (MASH)

The TMA shall have documentary evidence to prove that it has been successfully crash tested following the procedures set forth in the NCHRP Report 350 or MASH.

To allow the use of collision attenuator or TMA on the public roads.User shall ensure the following report/letter to Road Asset Regulation & Licensing (RARL) of LTA to show the compliance of the above-mentioned standards:

- A copy of crash summary report, together with sequential photos from ISO certified test centre qualified to conduct NCHRP Report 350/MASH impact tests; or

- A copy of acceptance letter/report from United States of America Federal Highway Administration (FHWA)

Installation

The TMA shall be installed by a workshop authorised by the TMA manufacturer in accordance with the Drawings approved by Vehicle Approval & Control (VAC) of LTA

Warning Devices and Retro-reflective sheeting

TMA warning devices and retro-reflective sheeting shall meet the following requirements:

TMA warning devices and retro-reflective sheeting shall meet the following requirements:

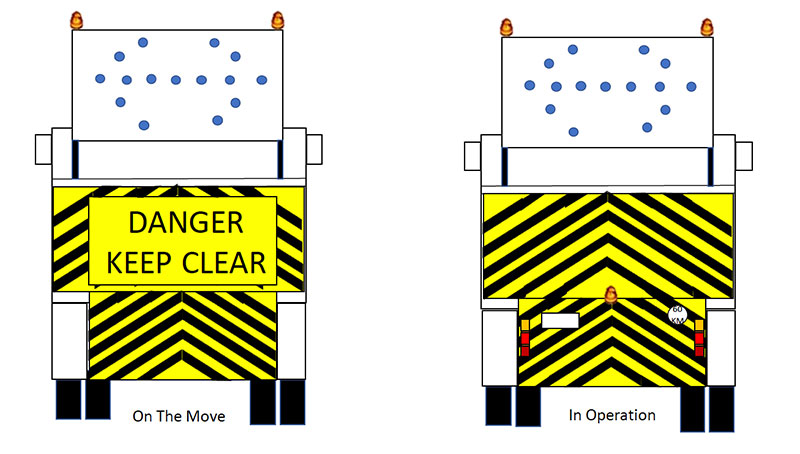

- 2 rotating lamps positioned beside the arrow-board and 1 rotating lamp at the rear of TMA. Rotating lamps installed on TMA shall comply with the latest prevailing version of United Nations Economic Commission for Europe (UNECE) Regulation 65 on Special Warning Lamps;

- Retro-reflective sheeting of black and florescent yellow green affixed at rear of TMA and rear of shadow vehicle. The retro-reflective sheeting specifications shall meet Type IX and above of the prevailing version of ASTM D4956.

- The flashing arrow board shall be mounted 2.5m above the road surface. The arrow board shall conform with the following specifications:

-

- Arrow board shall be a minimum of 1.8m (L) x 0.9m (H);

- Flashing lamps shall flash at a minimum rate of 65 flashes per minute during operations;

- Comprise a minimum of 15 flashing lamps with 140mm in diameter.

- Flashing arrow shall be clearly visible and legible from a minimum distance of 700m during day and night operations.

Longitudinal Bugger Distance

For mobile operations, the driver of the shadow vehicle shall remain in the vehicle at all times. The shadow vehicle shall be properly spaced behind the working vehicle. The shadow vehicle shall maintain a minimum longitudinal buffer distance of 30(1)m behind the working vehicle. This distance shall remain constant as the work progresses down the road/expressway.

For stationary operations, the shadow vehicle shall be properly spaced behind the work crew and maintain a minimum longitudinal buffer 15(1)m behind the start of work area.

| Types of TMA operation | Minimum Longitudinal buffer distance(m) |

|---|---|

| Mobile TMA | 30(1) |

| Stationary TMA | 15(1) |

Note:

Cross-check with TMA manufacturer’s recommended longitudinal buffer distance and adopt the longer buffer distance to be implemented on site.

Longitudinal Buffer Distance for TMA

TMA Manufacturer Trainer/Centre

The authorised training centre shall keep records and issue certificates to TMA operators. The certificate shall contain the following details:

- Name of the operator

- NRIC/FIN

- Date of training

- Model and serial number of TMA

TMA Operator shall produce the certificate for inspection, whenever is required by the Authority during their routine audit checks.

TMA Inspections, Maintenance and Repairs

To maintain the crashworthiness of the TMA, User shall ensure regular maintenance and inspection are carried out by TMA manufacturer’s authorised workshop.

User shall keep a copy of maintenance/inspection/and repair records issued by the manufacturer’s authorised workshop to ensure proper operation and the safety performance of the TMA. Requirements for inspection, maintenance and repair to be carried out by authorised workshop shall meet the requirements specified by the manufacturer.